Book Recommendation: Things Come Apart, Todd McLellan

As a kid I used to get myself into trouble for taking my toys apart. I didn’t know how to communicate to Mum and Dad the true value I felt when I understood what was going on inside, and how exciting it was to realize there were so many more things I needed to learn, like how electric motors, and transistors, and tape recording heads, and a hundred other things worked.

To take things apart was to collapse the wave function in a mentally constructed quantum-field I’d previously thought of as magic.

The record player Mum and Dad got me one Christmas, I got in DEEP TROUBLE for taking it completely apart to understand where the sound was coming from and what made the record turn. I stripped the electric motor down to the bare permanent magnets and unwound its copper wire coils to see how much wire it took to make it work. It could not be put back together and never worked again.

If you are a maker, a builder, a creator, there’s a high likelihood you’re curious about how others build and make things too. I think it is invaluable to see how others do their craft and to see what stuff they use...to see what’s inside their creation.

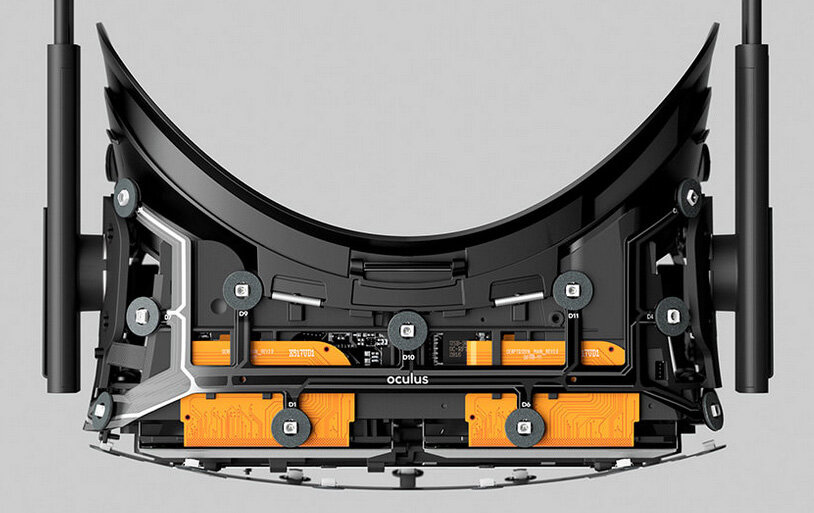

There’s tremendous insight you can gain from seeing what’s inside. Things we see and use every day contain hidden worlds where electronics and mechanisms and design all come together, sometimes beautifully, to make mundane things work.

Recently, I picked up a copy of “Things Come Apart” which has photographs of all the stuff inside 57 different products. Such as a two-page, exploded view of all 148 parts inside an old-school rotary telephone, and a five-page fold-out showing the 7,580 components used in a two-seater, light aircraft. This book gives a thorough overview, and in many cases enough detail that you can look closely at every part, for things small and ordinary to big and complex.

Want to know what’s inside your Amazon Echo? It’s there. Curious about how many electric motors are in a vending machine for frozen goods? Look and count them up.

Things Come Apart doesn’t show you how things get assembled, that’s often a trade secret and would probably require an entire book for each product included, but it does show you what is inside a broad swath of machines with enough detail to understand the gist of what’s involved in each product.

This book isn’t perfect, many components within items with a large part count are a bit too small to show real detail, but it does give a good idea of what’s inside a broad swath of stuff.

This book lets you notice clever mechanical optimizations, see standard parts and components you didn’t know existed, and find familiar materials used in unexpected places. You might even glean insight into how all these parts get assembled to deliver a product that will withstand the test of time, or conversely realize why some products have a limited lifespan.

Most of the things featured in this book have been through many iterations of optimization, resulting in the lowest cost bill-of-materials achievable along with an easy-to-assemble and test product.

While I would love even more detail on some of the things featured, It’s valuable for appreciating what is – and isn’t – inside a product. This insight might help inform an inventor or maker where it is and isn’t worth focusing effort in your own projects.

Unless you’re working on a one-off piece of art, a hobby, or a science experiment, a likely measure of success will be eventually related to the number of people buying or using whatever you’re making. In that case the need to optimize the build cost and design for ease of assembly is a must. Ignoring the inevitability of resource demands, and learning the hard way that it’s impossible to make your product at a cost the market can bear, or that many units and are next to impossible to fix, can and does result in the failure of a whole bunch of great ideas.

So as to avoid messes like this…

This book reminds makers that cost, reliability, and assembly are real concerns that you should keep in your noggin, to some degree, the entire time you’re developing because ignoring them might result in an expensive redesign or a product that launches dead in the water due to its unsustainable cost.

And even if what you’re making is a one-off or hobby project, seeing what’s inside all the things featured in this book might make you aware of a component you didn’t even know existed - that you might be able to order something you thought you’d need to invent from scratch to make your idea work.

Companies that make and sell things for profit have whole, sometimes extensive, teams focused on lowering the cost of materials, increasing assembly throughput, and optimizing final yield so nearly every-single-thing rolling off their production line works as expected.

This book offers independent makers the opportunity to learn from their hard work, and dollars spent optimizing, without needing to buy all these things and take them apart yourself. I mean, you could buy a two-seater plane and disassemble it, or you can take a look at the pictures in Todd McLellan’s book from when he took stuff apart.

I wonder if he got that airplane back together and working once he’d got the pictures he wanted?